Mezzanines

At Tecrostar we define the load evenly distributed per square metre. Therefore, the load capacity of mezzanines varies according to each model and its size. For detailed information on the load capacity of a particular mezzanine, we recommend consulting the corresponding technical datasheet.

In the case of some sturdier models, such as the XL Range, we also define the admissible concentrated point loads. These loads depend to a large extent on the board we use as the mezzanine floor, as it is the component that directly receives the load. Specific information on point loads can be found in the product description.

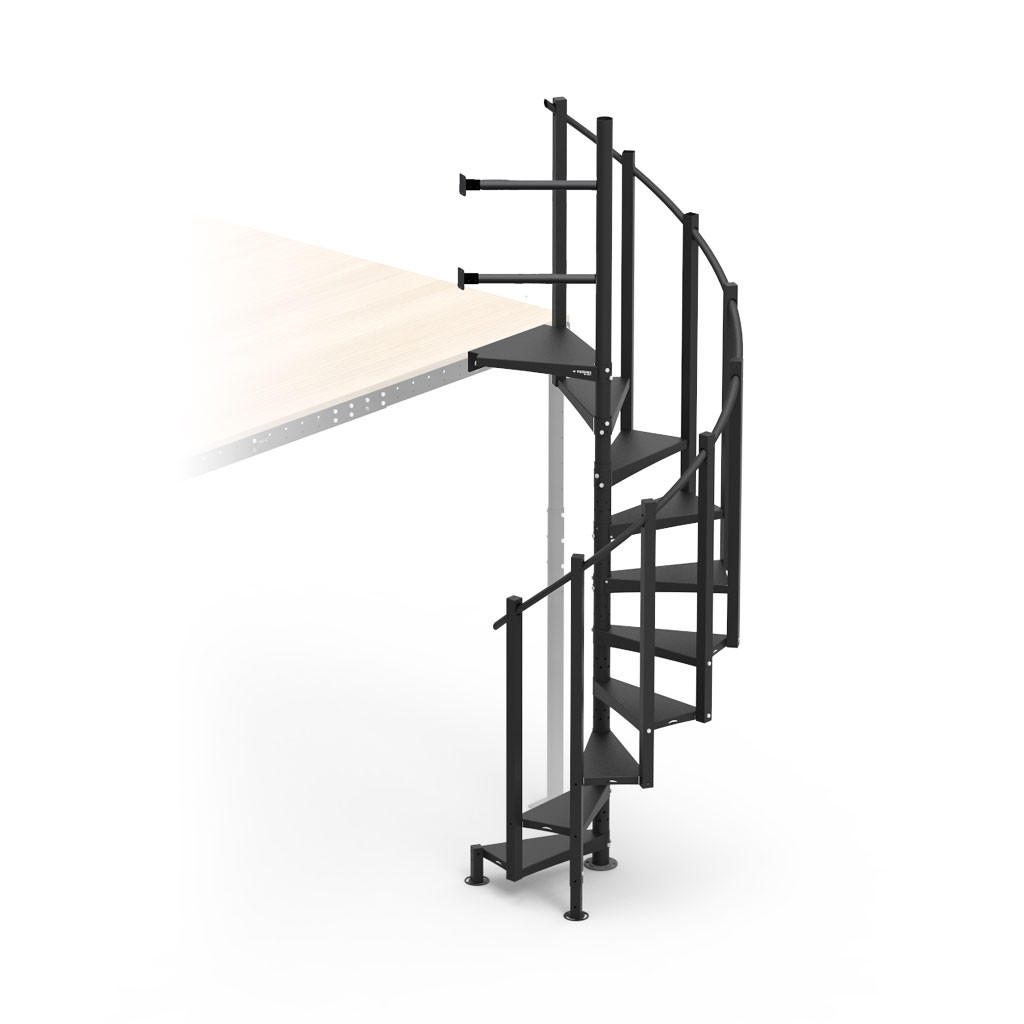

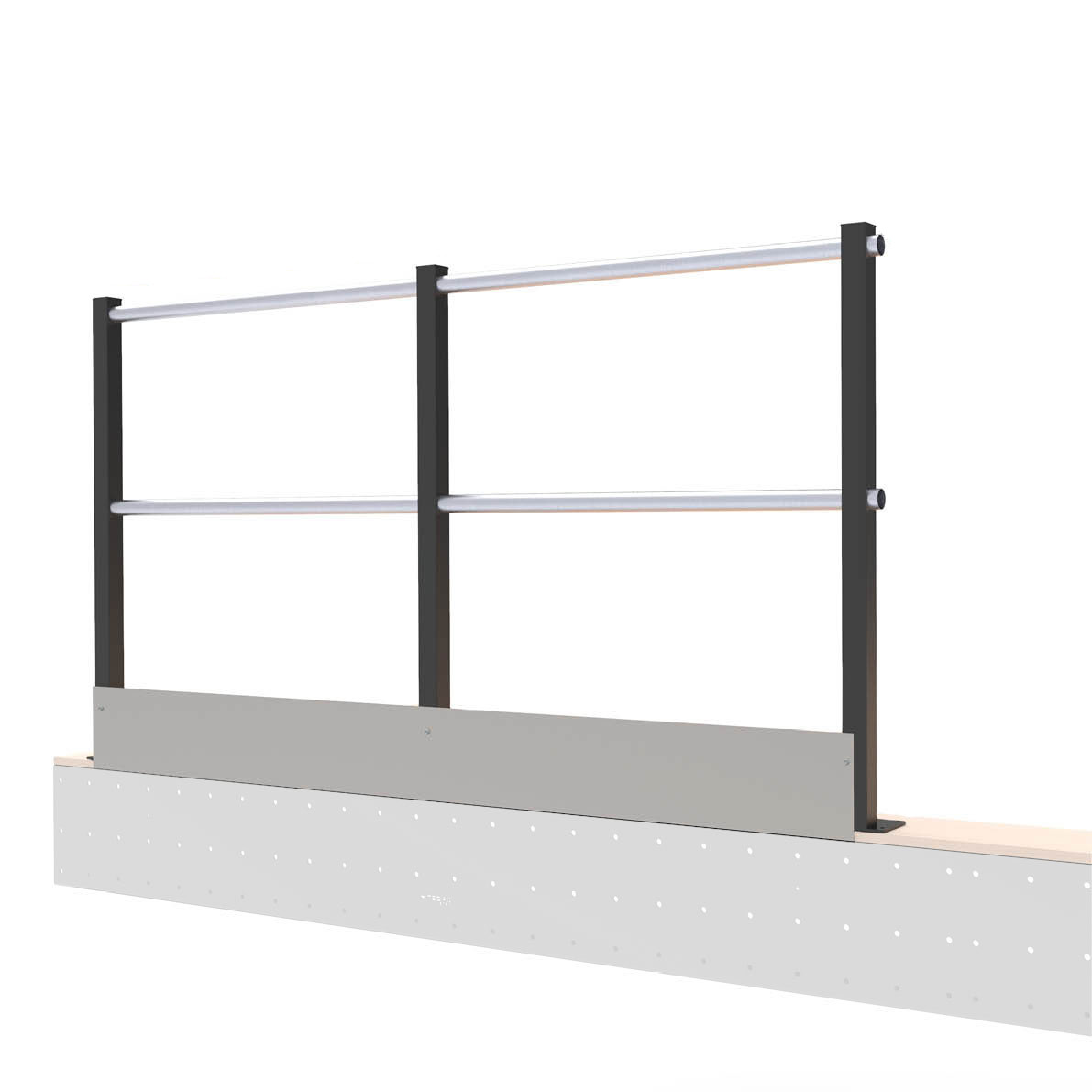

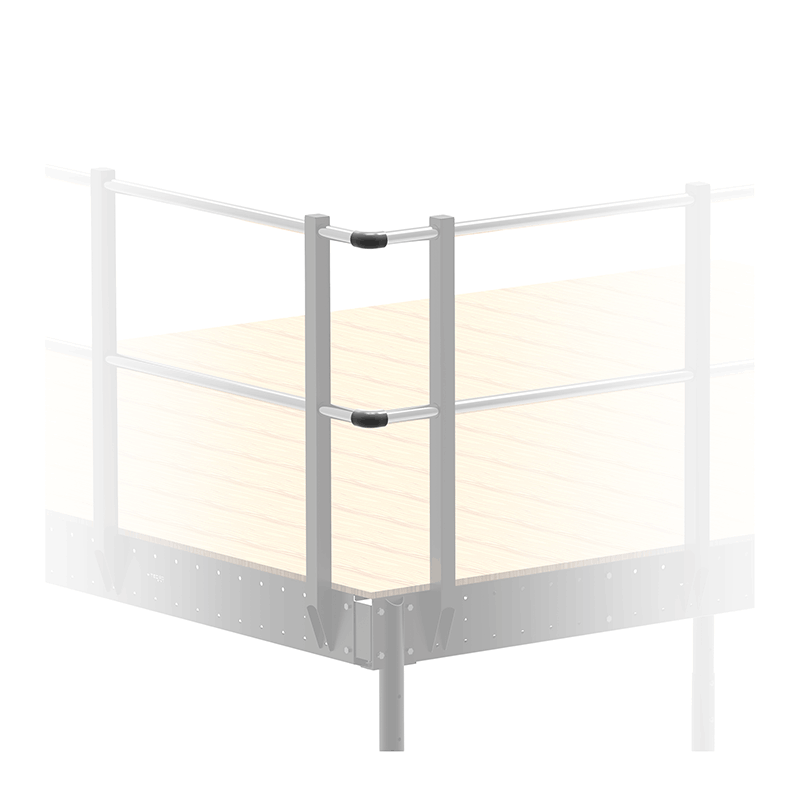

Steel parts such as frames, handrail posts and stair stringers are coated with an electrostatic polyester powder paint coating process for maximum adhesion, available in:

- White (RAL: 9016). Available from stock at no extra cost.

- Black (RAL: 9005). Available from stock at no extra cost.

- Micro-textured anthracite grey (RAL: 7016). Waterproof treatment is only available on a specific selection of products.

The mezzanines in the XL Range are available in:

- Yellow and black (RAL: 9005 and 1003). Available from stock at no extra cost.

This type of coating is perfect for indoor use. If you plan to install the mezzanine outdoors, we recommend consulting Can I install a Tecrostar mezzanine outdoors? This section contains information and recommendations to consider in order to improve its performance and durability.

Yes, the mezzanine floor is included.

For the S, M and L ranges we use 18 mm pine plywood structural panels, with tongue and groove joints on all four sides.

In the XL range, we use P5 HYDRO high-density particle board structural panels, with tongue and groove joints on all four sides and 35 mm thick.

If you want to install your mezzanine outdoors and take care of the floor, we recommend installing the Outdoor Decking. This product is placed over the flooring of the mezzanine, making it a suitable option for outdoor use. It is the ideal waterproof solution to protect the wood flooring and prolong the life of your outdoor mezzanine. In this way, you can create multifunctional spaces such as pergolas, porches, terraces or carports.

The kit includes as many boards as needed to install the mezzanine in its maximum dimensions.

To install the mezzanine in smaller dimensions, it is necessary to cut the boards as it is explained in the installation manual included in the mezzanine kit.

No. Tecrostar does not have a different flooring alternative. However, it is possible to personalize the finish of the floor by adding some accessories on the boards (carpet, platform,...). Check our floor finishes in accessories section. If the customer installs a different floor from the boards provided, it is their responsibility to ensure the resistance of the full mezzanine, since the floor contributes to the stability of the whole.

Plasterboard is a low density material, so you can make a closing wall on top of the mezzanine. You can also close the lower part of the mezzanine when mezzanine is indoors.

When the closing wall is made in mezzanines installed in the exterior, you should consult tecrostar, since lateral wind load can cause the structure needs stability kits.

No, you can’t. At the moment, our mezzanines are available just for a single height although some customers install them on another existing mezzanine. In that case, the resistance of the existing one should be checked.

It depends on the beam type, we need to calculate the corresponding surface load. For example, a secondary beam TM15 supports around 560 kg. You should take into account that if we apply additional loads, a part of the bearing capacity of the beam is being consumed.

If you have any doubt about important additional loads, contact our technical department.

*The columns of the XL and L mezzanines are made of structural-quality materials. Consequently, they have a fabrication mark related to the traceability which indicates the heat number, steel type,…

Yes. Provided that the inclination is small, we can use a wedge under the mezzanine columns to level it. If the inclination is too small it might be not necessary at all and the slope might be imperceptible.

Yes, you can because the structure does not to be in full contact with the wall. When the walls are irregular or when you want to work around a fixed object, the boards can be finished off against the wall. These factors must be taken into account:

- When the distance between the mezzanine and the wall is less than 10 cm, you can cover that surface with the board.

- From 10 cm to 30 cm, it is necessary to use the board flight support. You should buy as many supports as necessary according to the length of the surface you want to cover.

- For gaps greater than 30 cm, please contact the technical department.

The total board surface included with the mezzanines only covers the maximum surface area of the mezzanine floor. You can add panels to cover this additional surface.

Yes, it is possible to reduce the height but not to increase the maximum position.

To reduce the height of S and M mezzanines, you can ask the technical department for a type of short column. With their use the telescopic and adjustable system is maintained, but the maximum and minimum positions of the structure are reduced.

Depending on how short the mezzanine needs to be, the customer may have to make a simple cut on these columns.

To reduce the height of L and XL mezzanines, a special cut must be made. You can order this cut from Tecrostar and we will send you a personalized quotation.

Yes. This is quite common and the results are very good. The telescopic system of the columns enables the height to be adjusted every 6 cm.

Yes, you can. However, the maximum load capacity will be unaffected.

No, it is not a customised mezzanine but its telescopic design enables an almost customised finish. This system is length, width and height adjustable, achieving the preferred measurements.

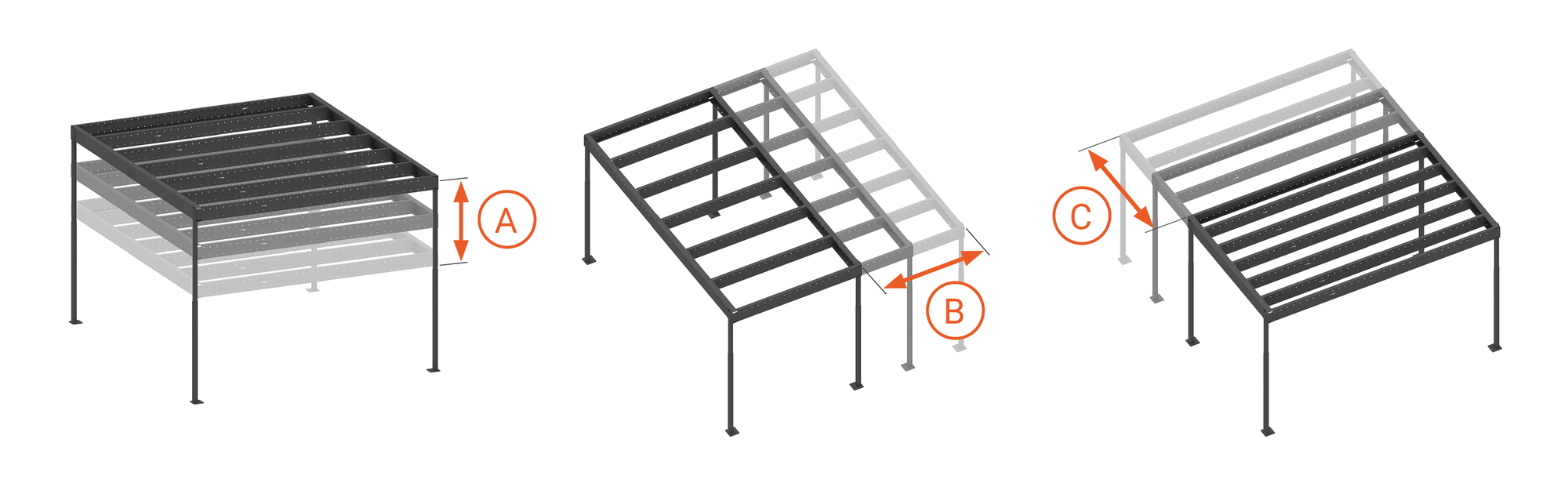

A: adjustable every 6 cm

B: adjustable every 10 cm

C: adjustable every 10 cm

In our shop, we offer two combinations: kits and packs.

In the case of the kits, you can choose the colour of the structure and the railings handrail .

In the packs we have carefully selected a combination of products that we believe will offer you a complete and convenient experience without the need to make additional choices. Therefore, the products in the packs cannot be changed.

We might have various models of mezzanine that meet the dimensions you need. In this case, follow these criteria:

1- Load-bearing capacity

2- Maximum span (Distance between columns)

3- Beam height

4- Height of the mezzanine above the decking you need

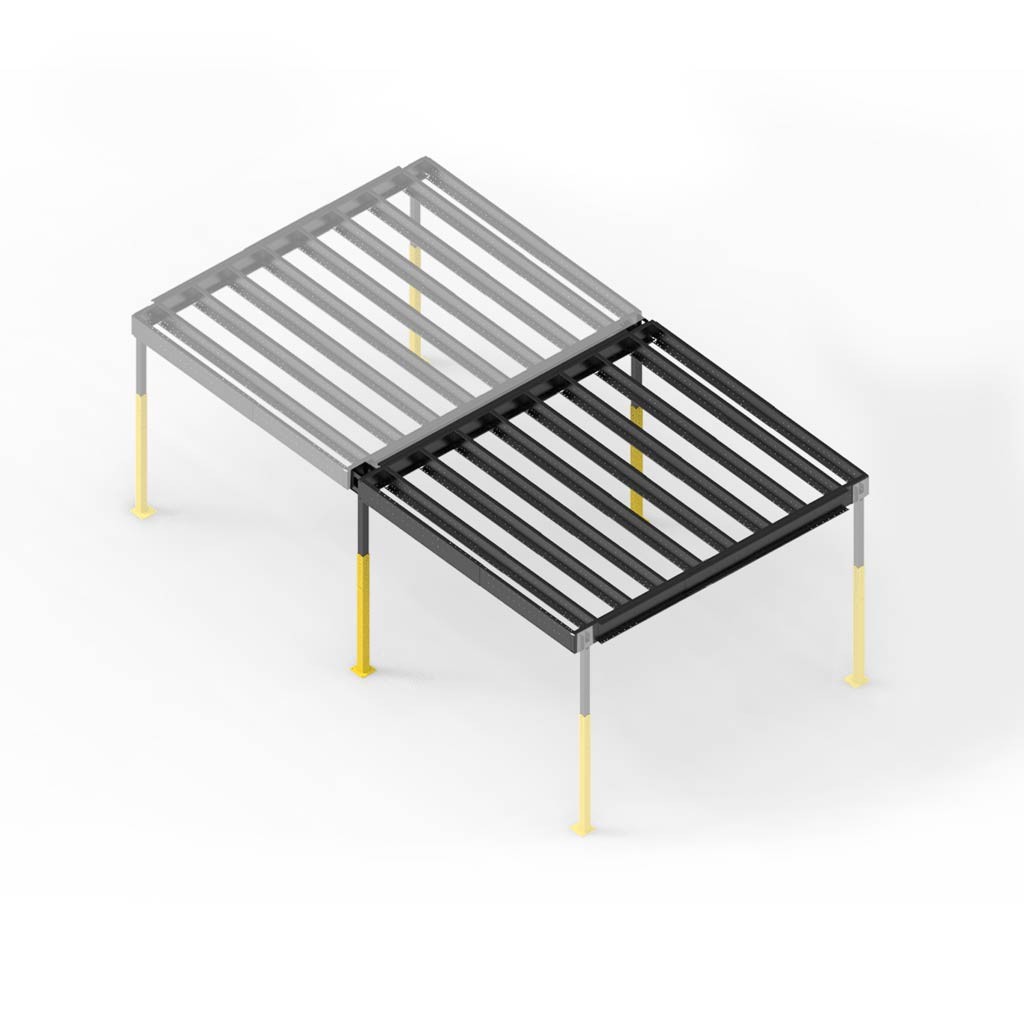

You can increase the surface using the extension kits. Get these kits at the same time as your mezzanine or in the future, when you need more space.

These kits are height-adjustable as well and allow to multiply the surface of our mezzanine.