Quality of the materials

Our products are designed with top-quality materials, ensuring efficient, safe and sustainable technical solutions. We combine steel, aluminium and wood, carefully selected to offer strength, durability and an aesthetic finish. In this quick guide we give you a simple overview of the materials we use, their properties, as well as some tips you should take into consideration to keep them in perfect condition.

1. Steel

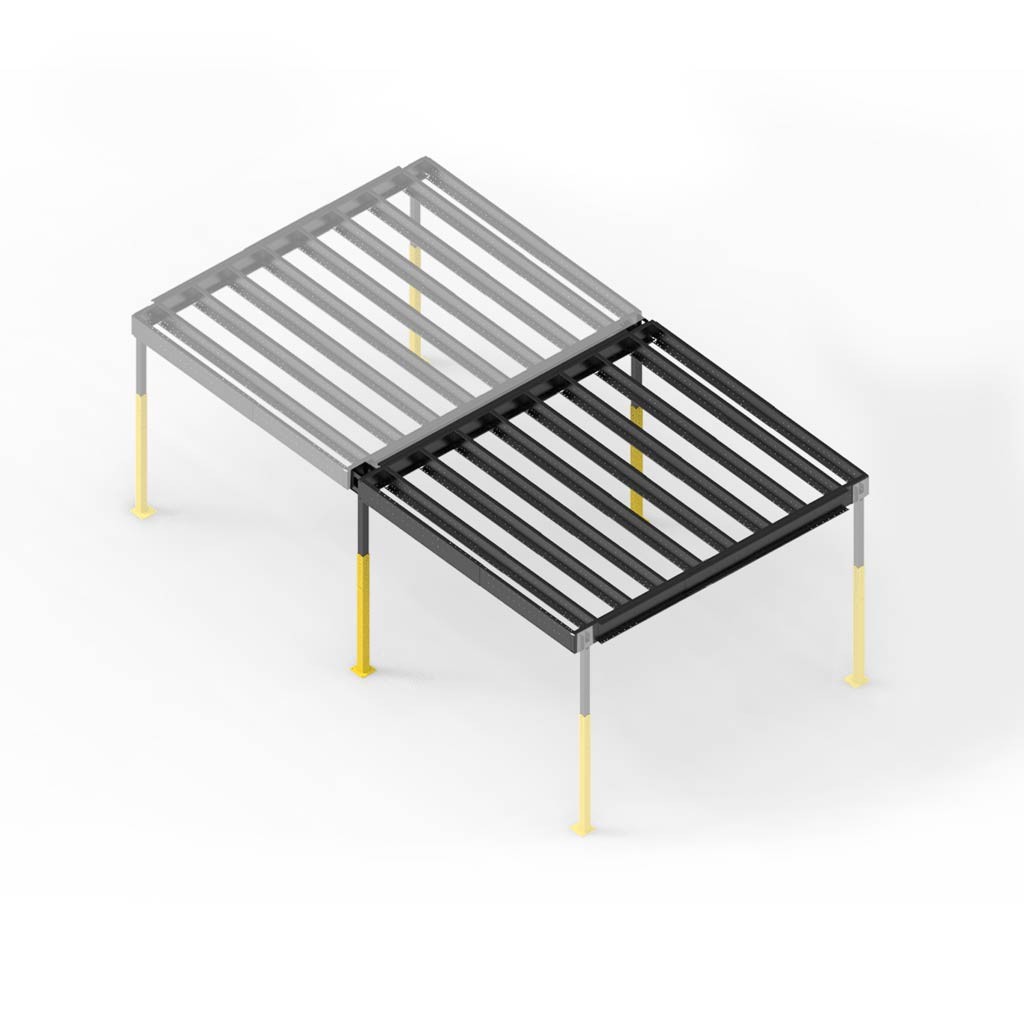

The steel we use in beams, pillars and other structural elements is very strong, has a high elastic limit and complies with different standards, such as S235, S275 and S355, depending on the requirements of each product. The steel parts are manufactured with advanced laser cutting, bending and forming technology, guaranteeing this way an impeccable finish. In addition, the steel is 100% recyclable, making it a sustainable option.

1.1 Lacquering of steel parts

The lacquering of the metal components is carried out by means of an industrial oven painting process with electrostatic adhesion, known as powder coating, which guarantees a long-lasting finish. This type of powder coating offers extra protection against corrosion and wear.

Considerations:

The lacquering is carried out using an automated process that guarantees a uniform finish. In the fastening areas, it is possible that a small mark may appear. This is almost imperceptible once mezzanines and/or staircases are installed. In this photo, you can appreciate this detail.

We advise you to treat the parts with care to avoid damage to the lacquer. However, if small marks appear, do not worry; these do not compromise the strength and stability of the structure.

1.2 Waterproof treatment

If you plan to install our products outdoors or in humid environments, we recommend applying the waterproof treatment to maximise corrosion resistance. See our Guide for outdoor use and Tecrostar warranty for full details on care and maintenance to ensure maximum durability.

2. Wood

The wood we use in Tecrostar products comes from sustainable woodlands in Spain and France, mostly with FSC and/or PEFC certification in Spain, which guarantees a responsible and respectful management of the environment, promoting biodiversity and a sustainable use of natural resources.

We use different types of wood, all selected to a quality standard that guarantees good aesthetic and physical properties. AB grade generally has a more uniform appearance and fewer imperfections, although some natural wood marks may appear. This means that, although we aim to provide an attractive finish, each piece of wood is unique due to the natural variations in the material.

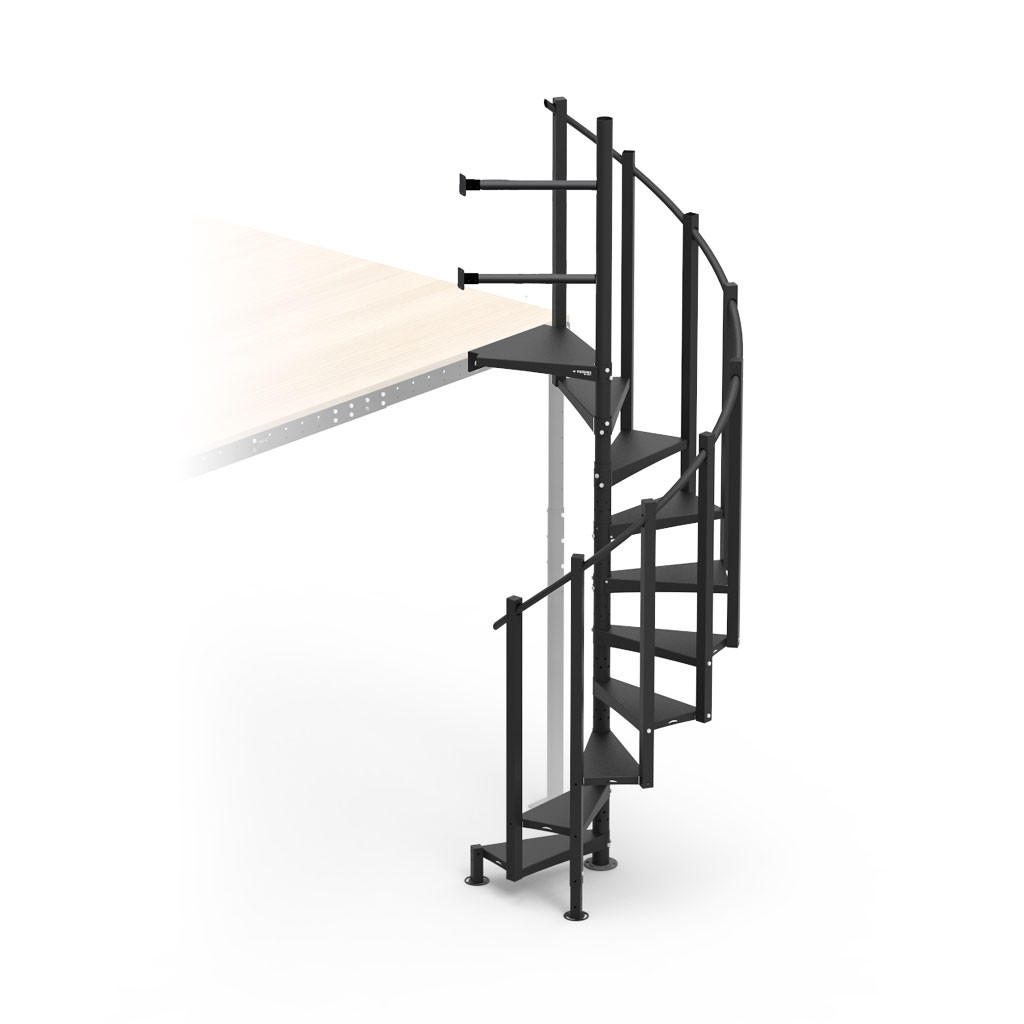

2.1 Handrail and Ladder

We use top-quality beech wood, known for its high density and strength. This wood is ideal for heavy use, which makes it perfect for steps and handrails. In addition, its fine, even texture gives it an elegant and natural look.

2.2 Boat ladder and wooden steps

These products are manufactured from radiata pine plywood, with repaired faces. They may show some natural wood marks. This means that, although we aim to offer an attractive finish, each piece of wood is unique due to the natural variations in the material.

2.3 Flooring boards

The boards used to build our mezzanine floors are tongue and groove on all four sides, which ensures a perfect fit between the panels. They can be of two types:

- European radiata pine plywood: It offers excellent structural strength, is easy to handle, and both sides are repaired to ensure a uniform, quality finish.

- High-density structural chipboard: This material provides stability and durability, with increased moisture resistance.

2.4 Outdoor decking

Our 3-layered decking consists of the following:

- Waterproof and breathable tarpaulin.

- Pine battens with Autoclave IV treatment.

- Pine slats with autoclave IV, treatment, which ensures extra resistance to the inclement weather.

Recommendations for wooden parts:

-

- Varnish or paint the wooden parts to protect them and achieve a more uniform finish. This will allow you to even out the tone and hide the natural grain of the wood.

-

- Apply filler to cover small indentations or imperfections that may appear on plywood due to natural knots in the wood. These marks do not affect the structural strength, but if you want a finer finish, sanding the surface after applying the filler will help to achieve a smooth, even result.

3. Structural hardware

The fasteners used in our products are of 8.8 quality, one of the strongest for structural applications. This guarantees a secure and stable fastening for any type of installation, resisting both static and dynamic loads.

Recommendations:

Periodically check screws and other fasteners to ensure that they are still tightened as required. These regular visual checks and maintenance will help to maintain the safety and stability of your products over time.

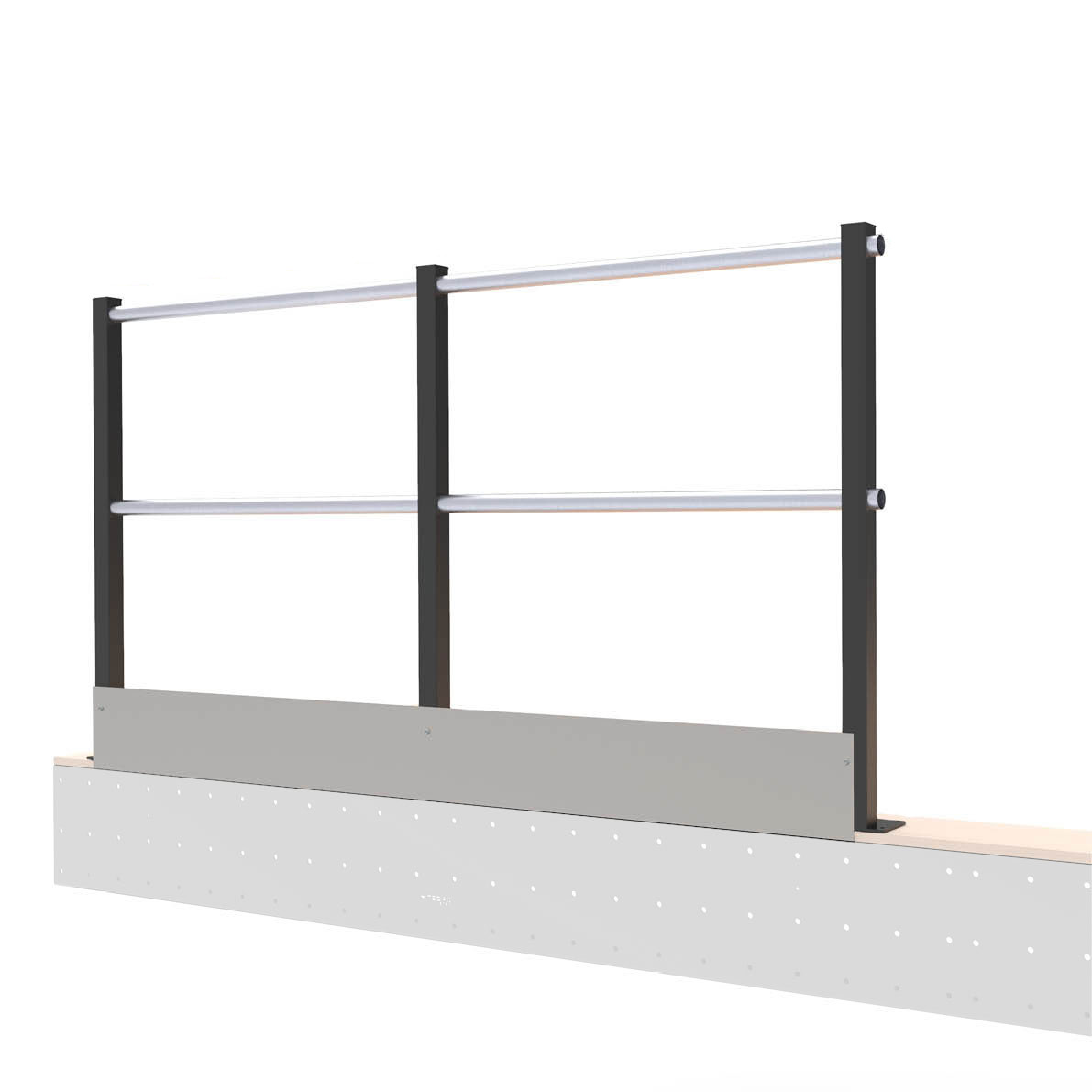

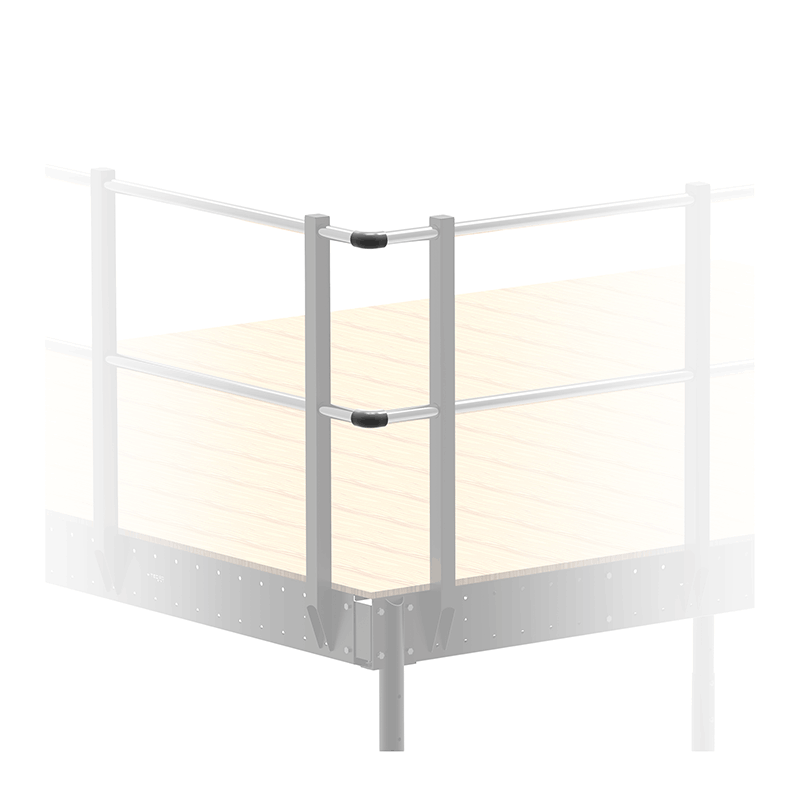

4. Anodised aluminium

The aluminium we use in some of our products is anodised, which makes it more resistant to corrosion and ideal for outdoor usage. The anodising process creates a protective coating on the aluminium, which not only protects it from wear and tear, but also enhances its appearance.

Anodised aluminium requires little maintenance and is an excellent choice for outdoor applications due to its durability and weather resistance. We recommend avoiding the use of harsh chemicals that may damage the anodised layer.

Certifications and Acknowledgements

The quality and safety of our products are guaranteed thanks to the certifications provided by our suppliers, endorsing both the materials and the manufacturing processes. In addition, we have been awarded the Gold Medal Award of Merit at INPEX (Invention and New Product Exposition), the largest invention fair in the USA. These achievements reflect our commitment to innovation and excellence, driving us to continue to provide high-quality solutions that meet our customers' needs.